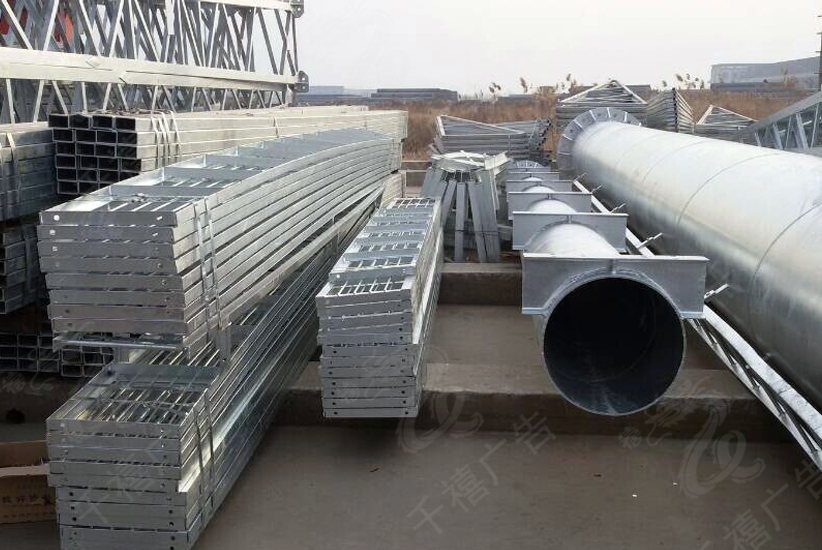

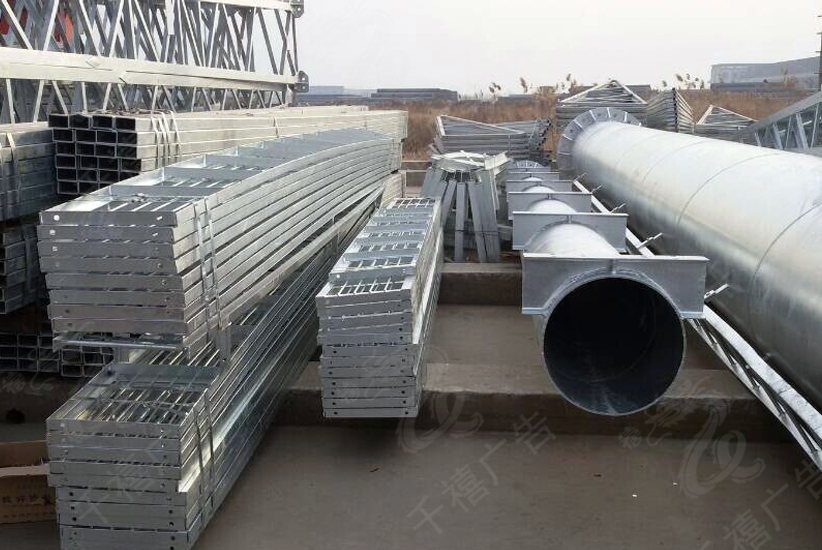

High-quality Galvanized Billboard completed

Galvanizing is divided into blow plating and hanging plating (cold plating and hot plating)

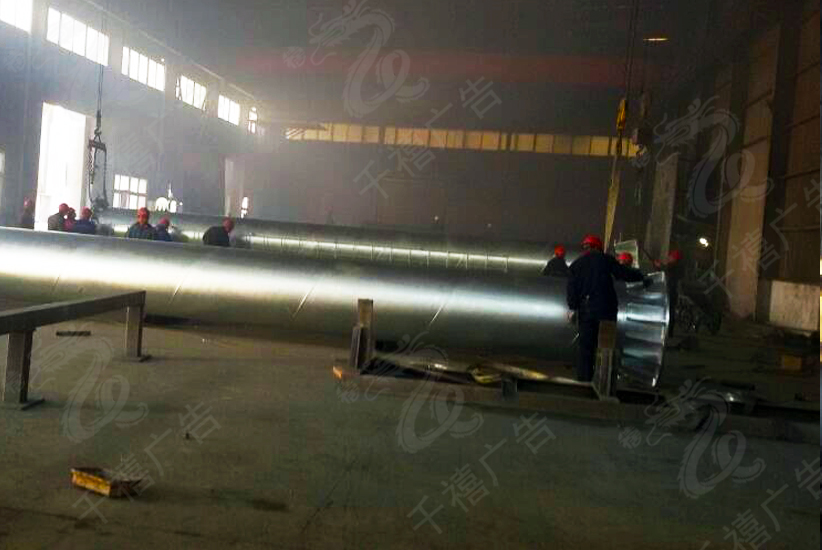

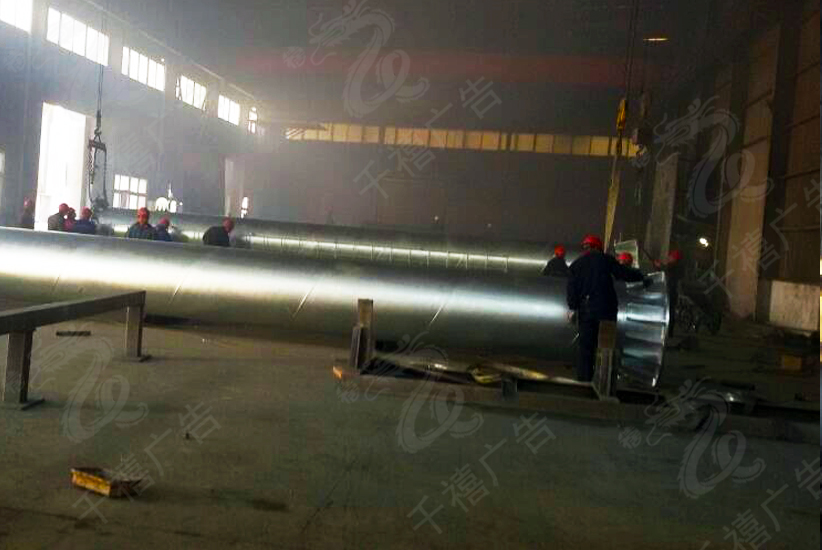

The three processing methods are mainly because the thickness of the zinc layer is different (the retention time of the zinc layer is also different), cold plating is the second, blow plating is the second, and hot plating is the most expensive. This time our company uses Hot-dip galvanizing, it is a method in which steel components are immersed in molten zinc to obtain a metal coating.

Quality requirements for galvanized accessories:

1. The outer surface of the steel pipe must not have oil stains (especially oil stains such as asphalt oil blending paint), otherwise it will cause a large number of unqualified products.

2. The steel pipe must be straightened after production to eliminate the internal stress of the steel pipe.

3. Uneven corrosion on the outer surface of the steel pipe cannot be galvanized, otherwise a lot of hydrochloric acid will be wasted.

4. There should be no artificial bending of steel pipes during transportation.

5. For steel pipes used for hot-dip galvanizing, it is not allowed to stick markers on the inner and outer walls of the steel pipe to avoid plating leakage.

After hot-dip galvanizing, the advertising tower accessories have thick zinc layer, strong corrosion resistance, better quality and longer service life. In some areas with harsh natural conditions, such as severe cold, strong wind, and summer exposure areas, galvanizing is more suitable Advertising tower.

Previous:Qianxi Tells You How Big A Billboard Is Suitable

Next:The steps and principles of making a three sided flip billbo

Our Target:

Try our best to be an outstanding outdoor advertising product manufacturer.

Our Mission:

Benefit more customers,and develop ourselves.